Shandong Huarui Electric Furnace Co., Ltd.

Shandong Huarui Electric Furnace Co., Ltd. was established in 2011

in Weifang City, Shandong Province, China, close to Qingdao Port.

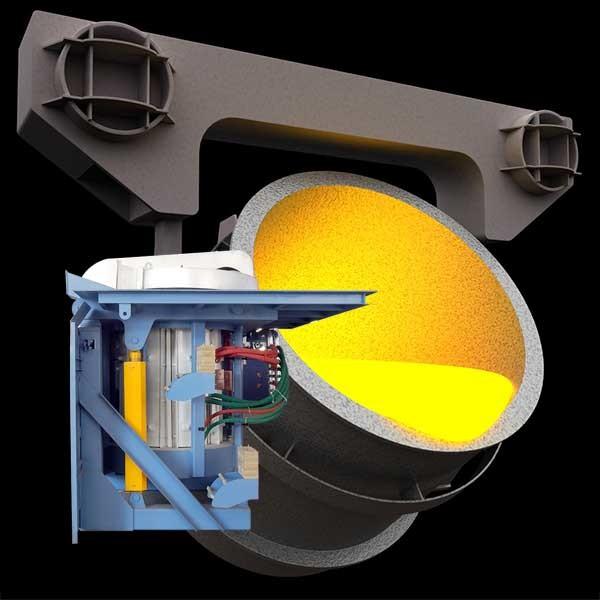

It specializes in the production of medium-frequency power

induction melting furnace systems, melting furnaces and

closed-water cooling systems.

All products adopt the latest international technology. With

advanced manufacturing equipment and scientific and rigorous design

and production processes, our product quality and technology are

always at the leading level in the industry. The safety, energy

saving, environmental protection, and other performance of our

energy-saving electric furnaces are much higher than the national

standards.

The fast energy-saving medium frequency melting furnace produced by

our company has a power of 100-30000KW and a capacity of 0.5T-60T.

It can save 15-20% of energy and is in a leading position in the

industry.